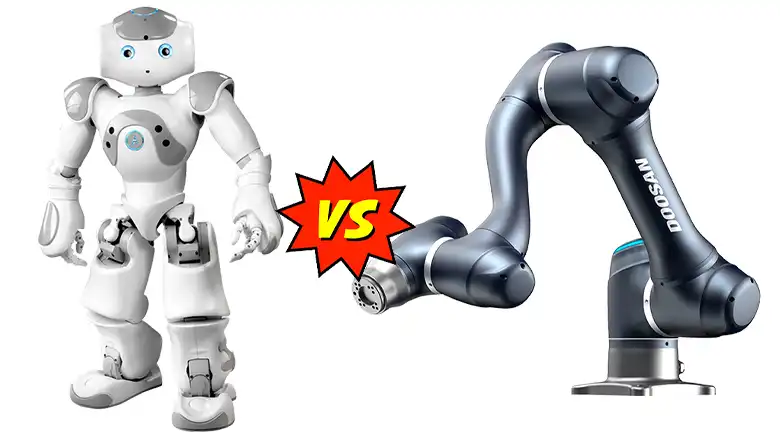

Traditional Robots vs Cobots

In the realm of automation, a transformative shift has been brewing. Traditional robots, with their rigid structures and limited capabilities, are facing competition from a new generation of collaborative robots, or cobots. These cobots are changing the way we think about automation, offering innovative features and advantages that set them apart from their traditional counterparts. In this article, we’ll delve into what cobots are, explore the distinctions between cobots and traditional robots, present a comprehensive comparison, highlight the advantages of cobots, and address some frequently asked questions.

What are Cobots?

Collaborative robots, commonly referred to as cobots, are a category of robotic systems designed to work alongside humans in a shared workspace. Unlike traditional robots, which often operate in isolation behind safety barriers, cobots are engineered to collaborate and interact directly with human operators. This cooperation is made possible through advanced sensors, intuitive programming, and an emphasis on safety features.

Cobots are designed to perform a wide range of tasks, from simple and repetitive actions to complex, high-precision activities. Their versatility and adaptability make them an ideal solution for numerous industries, such as manufacturing, healthcare, logistics, and even household tasks.

Key Differences between Cobots and Traditional Robots

Sensitivity to Human Presence:

- Cobots are equipped with sensors and software that enable them to detect the presence of humans in their proximity. When a human operator enters their workspace, cobots can slow down, stop, or change their trajectory to ensure safety.

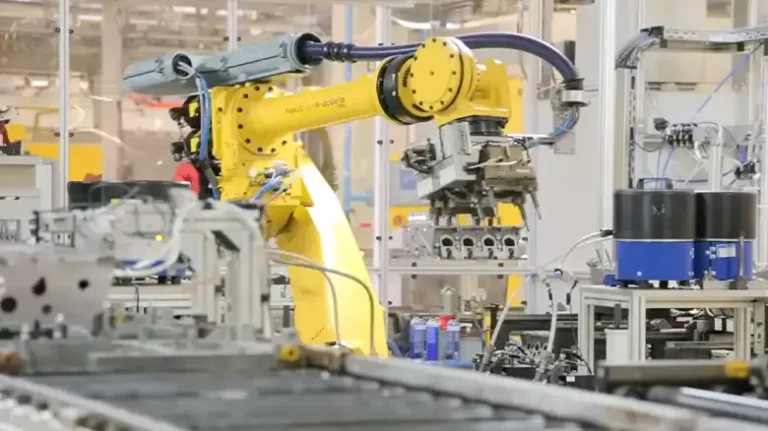

- Traditional robots typically lack this level of sensitivity to humans and often require physical barriers or cages to prevent accidental collisions or injuries.

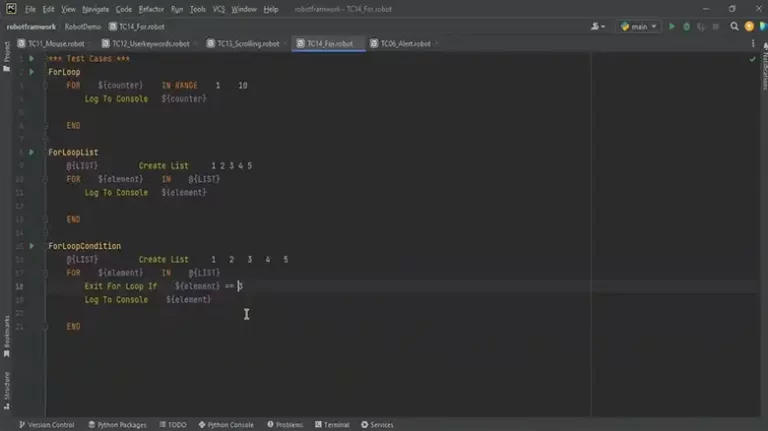

Ease of Programming:

- Cobots feature user-friendly interfaces that allow operators with minimal programming knowledge to teach the robot new tasks through demonstration or by manually guiding its movements.

- Traditional robots generally necessitate highly skilled programmers for complex programming tasks, making them less accessible for small and medium-sized businesses.

Adaptability:

- Cobots are designed to be highly adaptable, easily reconfigured to perform different tasks. They can be quickly redeployed to different parts of a production line or even different processes.

- Traditional robots often require extensive reprogramming and mechanical adjustments when transitioning to new tasks, making them less agile in dynamic manufacturing environments.

Safety Features:

- Cobots prioritize safety, with built-in features such as force-limiting technology and collision detection systems that mitigate the risk of harm to human workers.

- Traditional robots rely on physical barriers and safety measures, which can be expensive to implement and may hinder productivity.

Size and Mobility:

- Cobots are typically compact and lightweight, designed for easy integration into existing workspaces without the need for significant modifications.

- Traditional robots can be large and require dedicated spaces or extensive modifications to accommodate their size and range of motion.

Cost and Accessibility:

- Cobots are becoming increasingly affordable, making them accessible to a wider range of businesses, including small and medium-sized enterprises.

- Traditional robots often come with a higher initial cost, making them more suitable for large-scale manufacturing facilities with substantial budgets.

A Comprehensive Comparison

To provide a clear overview of the differences between traditional robots and cobots, here’s a comparison table:

| Aspect | Cobots | Traditional Robots |

| Sensitivity to Humans | Yes, with sensors and software | Limited, often require physical barriers |

| Ease of Programming | User-friendly interfaces | Typically require skilled programmers |

| Adaptability | Highly adaptable | Less adaptable, extensive reprogramming |

| Safety Features | Built-in safety features | Reliance on physical barriers |

| Size and Mobility | Compact and mobile | Larger, require dedicated spaces |

| Cost and Accessibility | Increasingly affordable | Higher initial cost |

Advantages of Cobots over Traditional Robots

Improved Safety

The foremost advantage of cobots is their ability to work safely alongside humans. They are equipped with advanced safety features that reduce the risk of accidents and injuries. This not only safeguards human workers but also eliminates the need for costly safety infrastructure like cages and barriers.

Flexibility and Adaptability

Cobots excel in environments where tasks change frequently. They can be quickly reprogrammed and redeployed, making them highly versatile. Traditional robots often require significant downtime and reconfiguration for task changes.

Ease of Programming

Cobots are designed to be user-friendly, allowing non-experts to teach them new tasks. This lowers the barrier to entry for businesses that lack specialized programming expertise.

Space Efficiency

Their compact size and mobility make cobots space-efficient, allowing them to operate in constrained workspaces. Traditional robots may require larger areas and extensive infrastructure.

Cost-Effectiveness

While the initial cost of cobots has decreased, traditional robots can be prohibitively expensive, especially for smaller businesses. Cobots offer an affordable automation solution.

Improved Productivity

Cobots can enhance productivity by taking over repetitive or strenuous tasks, reducing human fatigue, and allowing employees to focus on more value-added activities.

Quick Return on Investment (ROI)

Due to their lower upfront costs and increased productivity, cobots often provide a faster ROI compared to traditional robots.

Are cobots completely safe to work with?

Cobots are designed with safety in mind, but their level of safety depends on how they are programmed and used. With proper programming and adherence to safety guidelines, they can be very safe. However, operators should always be cautious and aware when working with any robotic system.

Can cobots completely replace traditional robots in all industries?

While cobots have numerous advantages, they may not be a suitable replacement for traditional robots in all industries. Traditional robots are still preferred in heavy-duty, high-speed manufacturing processes. Cobots are better suited for tasks requiring human-robot collaboration.

Do cobots require constant monitoring and supervision?

Cobots can operate autonomously for many tasks but may benefit from occasional monitoring, especially when working with new or complex operations. Operators can easily step in and guide cobots if needed.

What industries benefit the most from cobots?

Cobots find applications in various industries, including manufacturing, healthcare, agriculture, logistics, and more. They are particularly valuable in industries where tasks are repetitive, require precision, or involve frequent human-robot interaction.

How do I decide whether to invest in cobots or traditional robots for my business?

The decision between cobots and traditional robots depends on your specific needs, budget, and the nature of your operations. Consider factors such as the type of tasks, safety requirements, available space, and budget constraints. Consulting with a robotics expert can help you make an informed decision.

In Summary

The rise of cobots represents a significant shift in the world of automation. Their ability to collaborate safely with humans, ease of programming, and adaptability make them a valuable asset to industries seeking increased efficiency and productivity. While traditional robots still have their place in manufacturing, the advantages of cobots, including improved safety, cost-effectiveness, and versatility, are driving their adoption across a wide range of industries. As technology continues to advance, it’s likely that cobots will become an even more integral part of our daily lives and work environments, revolutionizing the way we think about automation.