How Cabot’s Work with AI?

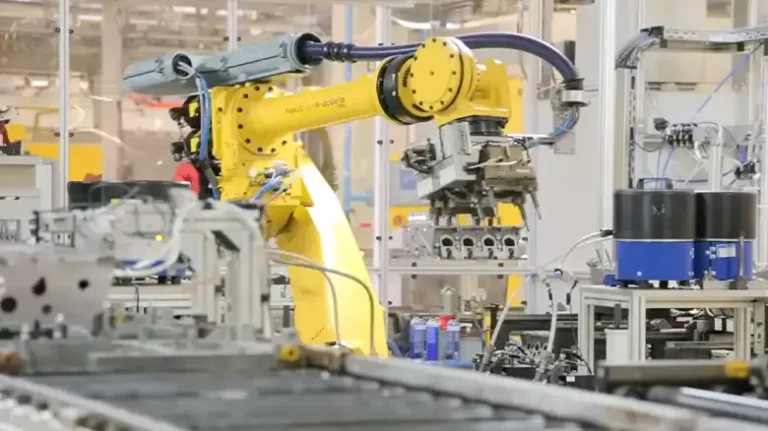

Collaborative robots, or cobots, have rapidly gained popularity in industrial and manufacturing environments for their ability to work alongside humans. These robots are not just autonomous machines; they can be supercharged with artificial intelligence (AI) to enhance their capabilities, adaptability, and safety.

Below, we will explore the various ways in which cobots work with AI, the advantages of this integration, the challenges that come with it, and the potential future developments in the field.

Different Ways in Which Cobots Work with AI

1. Sensing and Perception

Cobots are equipped with a range of sensors, including cameras, lidar, depth sensors, and force/torque sensors. These sensors provide the cobot with the ability to perceive its surroundings and interact with objects. AI algorithms process the sensor data, enabling the cobot to identify objects, recognize obstacles, and make informed decisions based on the environment.

One example is in a pick-and-place application. AI algorithms can help the cobot identify the shape and location of objects, making it capable of picking up items with precision and adjusting its grip if necessary.

2. Task Planning and Control

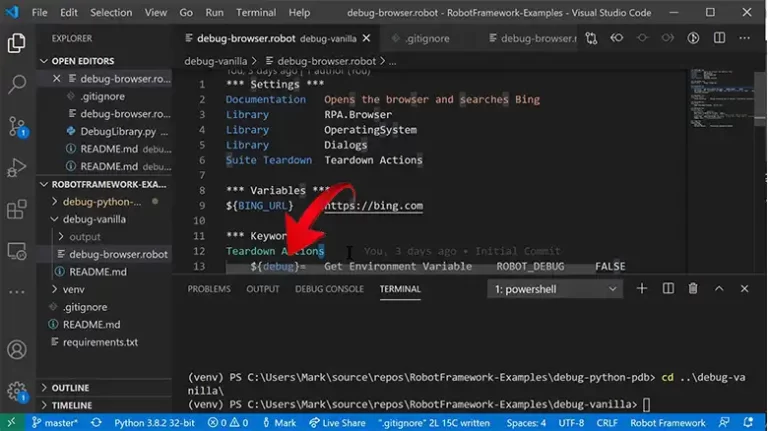

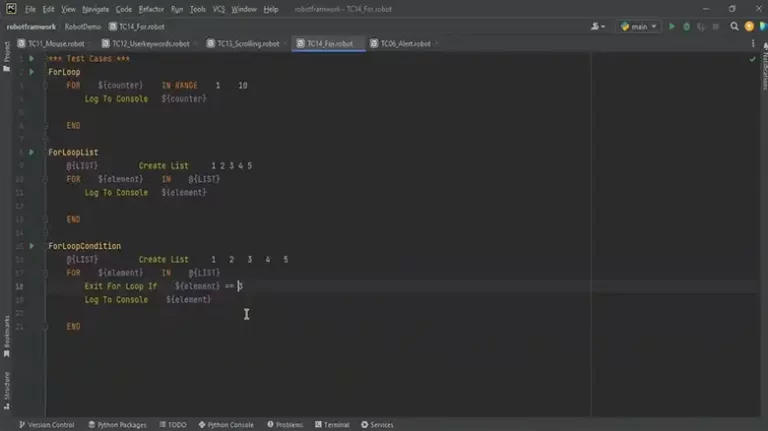

AI is employed to plan and control the movements of cobots. These algorithms take into account the environment, task requirements, and safety considerations to create efficient and safe trajectories for the robot.

In manufacturing, cobots can be programmed to follow optimized paths that maximize efficiency while avoiding collisions with other objects and humans. AI helps in real-time path adjustments to accommodate changes in the environment.

3. Object Recognition and Manipulation

Cobots can be trained to recognize and manipulate objects. This is particularly useful in industries where objects vary in shape, size, and weight. Machine learning techniques are used to teach the cobot how to handle different objects.

For instance, in an assembly line, a cobot equipped with AI can pick up different parts and assemble them precisely. It can adapt to variations in parts and ensure high-quality output.

4. Human-Robot Interaction

AI facilitates the interaction between cobots and human workers. Natural language processing and computer vision technologies enable cobots to understand and respond to verbal and non-verbal cues from humans.

In a collaborative setting, a cobot can respond to voice commands, hand gestures, or even a worker’s body language. This level of interaction makes the cobot a more intuitive and cooperative team member.

5. Safety Monitoring and Collision Avoidance

Safety is paramount when cobots work alongside humans. AI plays a crucial role in ensuring a safe working environment. Safety systems use AI to monitor the positions of humans and objects in the workspace.

In the event of a potential collision, the cobot can slow down or stop its movements to prevent accidents. This real-time adjustment is critical for maintaining the safety of both the cobot and human workers.

6. Continuous Learning and Adaptation

Cobots can be programmed to continuously learn and adapt. Machine learning and reinforcement learning algorithms enable cobots to improve their performance over time and adapt to changing conditions and tasks.

As a cobot repeats tasks, it learns from its experiences and becomes more efficient. This adaptability is especially valuable in dynamic manufacturing environments where product lines may change frequently.

7. Quality Control and Inspection

In industries where quality control is paramount, AI-powered vision systems integrated into cobots play a crucial role. These systems can identify defects or anomalies in products and perform corrective actions as needed.

For example, a cobot can visually inspect products and reject those with defects. This ensures consistent product quality and reduces the need for manual inspections.

8. Data Analytics and Optimization

AI is also used for data analytics in cobot operations. The data collected during cobot tasks can be analyzed to identify areas for improvement, optimize processes, and make real-time adjustments to maximize efficiency.

By analyzing data, manufacturers can identify bottlenecks in their processes, reduce waste, and improve overall productivity. AI can provide valuable insights for continuous process optimization.

Advantages of Integrating AI with Cobots

1. Increased Productivity

The integration of AI with cobots leads to increased productivity. Cobots can work continuously without fatigue, and their ability to adapt to different tasks and environments makes them highly versatile. This results in faster and more efficient operations.

2. Improved Quality Control

Cobots with AI can perform precise and consistent tasks, which is especially important in quality control and inspection processes. This reduces the likelihood of defects and ensures a high level of product quality.

3. Enhanced Safety

Safety is a significant advantage of integrating AI with cobots. AI-powered safety systems and collision avoidance algorithms make cobots safer to work with, reducing the risk of accidents and injuries in collaborative environments.

4. Labor Optimization

By automating repetitive and physically demanding tasks, cobots can free up human workers to focus on more complex and creative aspects of their jobs. This leads to a more balanced and fulfilling work environment.

5. Adaptability

Cobots with AI can adapt to changing tasks and product variations, making them suitable for industries with dynamic manufacturing needs. This adaptability reduces the need for reprogramming and reconfiguration.

Challenges and Potential Future Developments

1. Cost of Integration

One of the challenges of integrating AI with cobots is the initial cost. Developing and implementing AI systems can be expensive. However, as technology advances and adoption increases, costs are likely to decrease.

2. Technical Complexity

Integrating AI with cobots requires expertise in both robotics and artificial intelligence. Companies need to invest in training or hire professionals with the necessary skills to ensure successful integration.

3. Ethical Considerations

The use of AI in cobots also raises ethical concerns, particularly in terms of job displacement and data privacy. Companies must address these concerns and implement responsible AI practices.

4. Data Security

Data security is a concern when integrating AI with cobots. These systems collect and process data, which must be protected from cyber threats and breaches.

5. Regulatory Compliance

Cobots working in various industries may be subject to specific regulations and standards. Companies need to ensure that their AI-integrated cobots comply with these regulations.

Can cobots with AI completely replace human workers?

Cobots are designed to work collaboratively with humans, not to replace them. They are meant to automate repetitive and physically demanding tasks, allowing humans to focus on more complex and creative aspects of their jobs.

What industries benefit the most from AI-integrated cobots?

Industries with repetitive tasks, quality control requirements, and dynamic manufacturing needs, such as automotive, electronics, and food production, benefit significantly from AI-integrated cobots.

How do AI-integrated cobots impact job opportunities?

While AI-integrated cobots may reduce the demand for certain repetitive tasks, they can also create new job opportunities in the fields of robotics, AI, and cobot maintenance and programming.

What are the future developments in the field of AI-integrated cobots?

The future of AI-integrated cobots may involve advancements in AI algorithms, increased affordability, enhanced adaptability, and a broader range of applications across various industries.